hanwha xlpe compound price

with the new production procedure from hanwha xlpe products are provided at reasonable price

the compound being a much-improved version of pe has properties which greatly enhance its efficacy in different applications

Following is a list of how xlpe material out preform pe

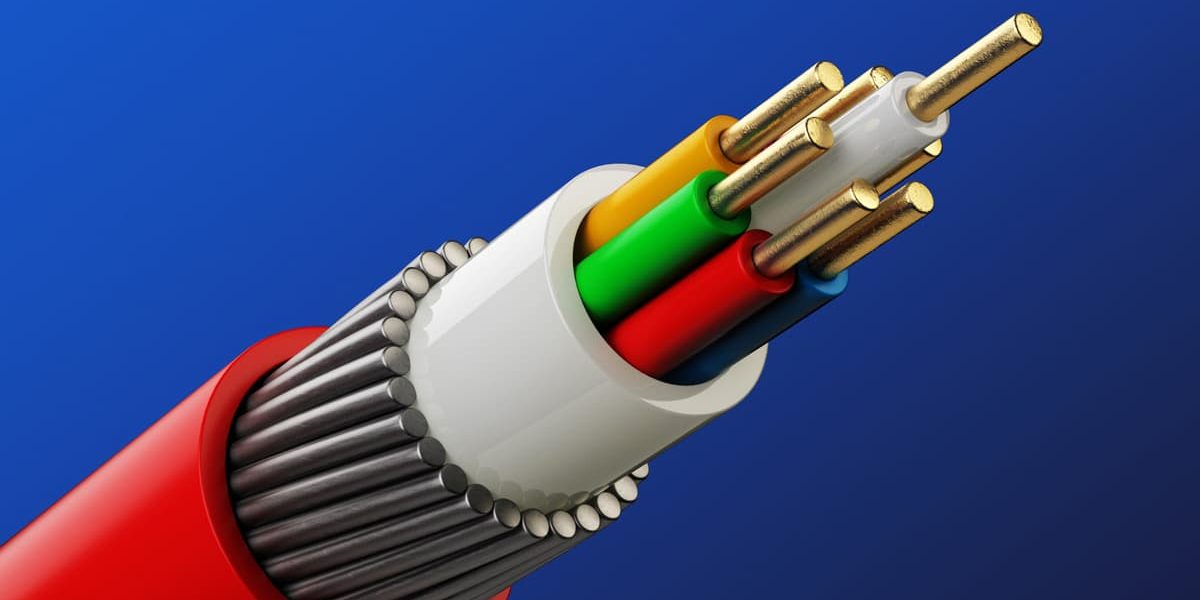

Cables are manufactured from polyethylene

Due to the significant amount of electricity transferred through cables at high temperatures, the insulation must be supported by cross-linking PE

Utilizing chemical cross-linking agents such as dicumyl peroxide, this is accomplished

After being crushed and heated, the reagent initiates a process of self-sustenance

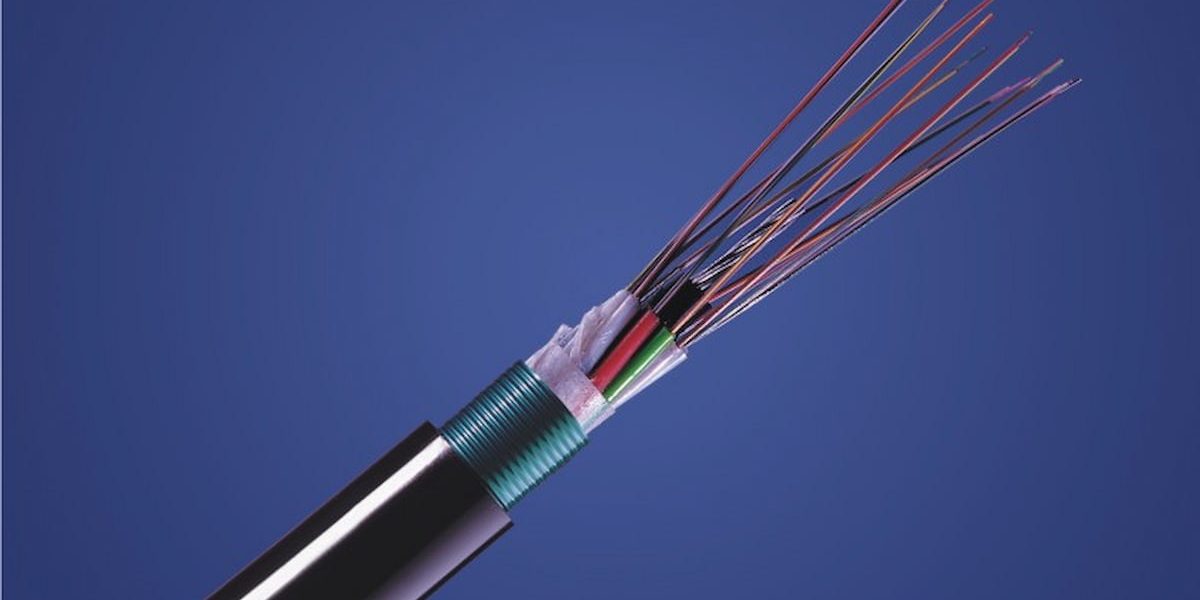

Cross-linking, however, produces by-products that must be eliminated from the cable in order to meet dielectric, mechanical, and electrical testing and performance requirements

Decompression procedure Degassing or heat treatment is a crucial stage in the manufacture of cables

After XLPE material has been subjected to heat treatment, a variety of analytical techniques can be utilized to measure the degassing process

Polyethylene (PE) is a ubiquitous plastic used in building, packaging, and industrial settings

PE is categorized as a hydrocarbon polymer, meaning it is composed of hydrogen and carbon atoms

It is hence non-polar, water-insoluble, and melts at high temperatures

PE is not biodegradable, either

XLPE is PE that has been chemically treated to increase its oxidation and corrosion resistance

This is accomplished by using antioxidants and stabilizers

XLPE is less expensive than ordinary polyethylene, making it a preferred material for sectors that require durable goods

However, XLPE has several downsides

First, it is heavier than ordinary PE, making transportation more challenging

Second, it is more susceptible to cracking over time because it is more susceptible to UV light

XLPE is frequently utilized in electrical equipment, such as transformers, cables, and switchgear

Additionally, it is utilized in pipes, tanks, and shipping containers

The thermoplastic polymer generated from ethylene is called polyethylene (C2H4)

Polyethylene is frequently utilized in packaging materials, food storage containers, pipelines, tubing, and several other industrial applications

High density polyethylene (HDPE) and low density polyethylene are the purest types of polyethylene (LDPE)

HDPE is more rigid than LDPE, making it suitable for usage in pipelines, but LDPE is more flexible, making it perfect for flexible applications such as bags and liners

The plasticizer XLPE is a copolymer of ethylene and vinyl acetate (EVA)

The esterification of acetic acid and ethanol yields EVA

As a monomer, vinyl acetate is used to create acrylic fibers and polymers

Since XLPE is a copolymer, it is not homogenous

There are various forms of XLPE, such as LLDPE, LLDPE/EVA, VLDPE, and VLDPE/EVA

LLDPE is a linear low density polyethylene copolymer consisting of long-chain and short-chain alpha olefins

LLDPE has a molecular weight of around 2 million Daltons on average

LLDPE is comparable to HDPE but less expensive because extrusion at high temperatures is unnecessary

VLDPE is a linear medium density polyethylene copolymer comprising alpha olefins with long and short chain lengths

The average weight of molecules is 4 million Daltons

VLDPE is comparable to LDPE, however due to decreased production costs, it is less expensive

hanwha xlpe compound

When making a decision between different kinds of cables for a project, you may be faced with the choice between installing PVC insulated cable and XLPE cable hanwha suggests the use of the most recent compound of xlpe, because it comes with benefits that meet many of construction needs today

Polyethylene is a typical material used for pipelines, pails, and containers

Polyethylene is a translucent, stiff, temperature- and sunlight-resistant material that is also transparent

Ideal for usage in grow rooms with fluctuating temperatures throughout the day

It is ideal to see what’s going on within the grow room due to the clarity

High density polyethylene (HDPE) and low density polyethylene (LDPE) are both utilized in cannabis production (LDPE)

HDPE is more expensive than LDPE, but it is more durable and has a longer lifespan

Both polymers have their benefits and drawbacks

hanwa standard construction cables are insulated and sheathed with polyvinyl chloride (often referred to as PVC) because it is a highly effective material for general-purpose electrical and physical protection

For instance, it is suitable for insulating and wrapping hanwa Twin and ground wires, in addition to numerous other typical architectural cables

However, if greater conductor temperatures are necessary, causing the cable temperature to exceed 70 °C, XLPE-insulated cables should be used for this purpose

XLPE has a maximum working temperature of 90°C, whereas PVC has a maximum working temperature of 70°C, which is required for standing building cables

The conductors of cables insulated with XLPE can carry high currents

The thermoset nature of XLPE enables it to endure high temperatures, whereas PVC is a thermoplastic

This means that the molecules in XLPE are chemically linked, making them more robust and adding to the cable’s overall thermal stability

It also increases other qualities, including as resistance to cracking and aging

At temperatures up to 90°C, cross-linked polyethylene insulation retains its tensile strength, elongation, and impact resistance, and does not melt or drip

In addition, XLPE insulation can tolerate conductor temperatures of up to 250oC for one second under short-circuit conditions, whereas PVC cables can withstand conductor temperatures of up to 160oC for one second, giving XLPE insulation a greater overload capacity in emergency scenarios

Additionally, it is 100 times more resistant to moisture than PVC and can sustain vibration

How does hanwa utilize this innovation? hanwa has spent decades researching these materials, refining their performance via tens of thousands of tests to guarantee that all cables are constructed to the highest standards

Over the course of the past century, we have become content specialists

Therefore, you may feel assured that, for instance, your trusted twin and ground cable or a low-smoke range specialty cable will be insulated with the optimal insulation for its application

Xlpe insulation enables scientist to creates form the basis of this compound qualities such as flame retardancy fire resistance or even smokeless wire and cable for situations like hospitals or smelting factories or fires stations and many more sensitive sites

Where normal wire and cable is not sufficient