Introducing xlpe armoured cable + the best purchase price

Underground cable is often armoured because they need to keep it protected form corrosion, damage, or even rodents eating the cable cover away and the price of armoured cable is higher than unarmoured cable

Xlpe as a sturdy offshoot of PE is an ideal option in the case of armoured cable

1

armored XLPE cable Extra Low Permeability Electrical Insulation is the abbreviation for XLPE

XLPE is a typical electrical insulator utilized in subterranean power cables

XLPE possesses exceptional resistance to oil, water, and other chemicals

It is resistant to severe temperatures and extremely resilient

XLPE is utilized in high-pressure applications that are exposed to water, oil, or corrosive substances

2

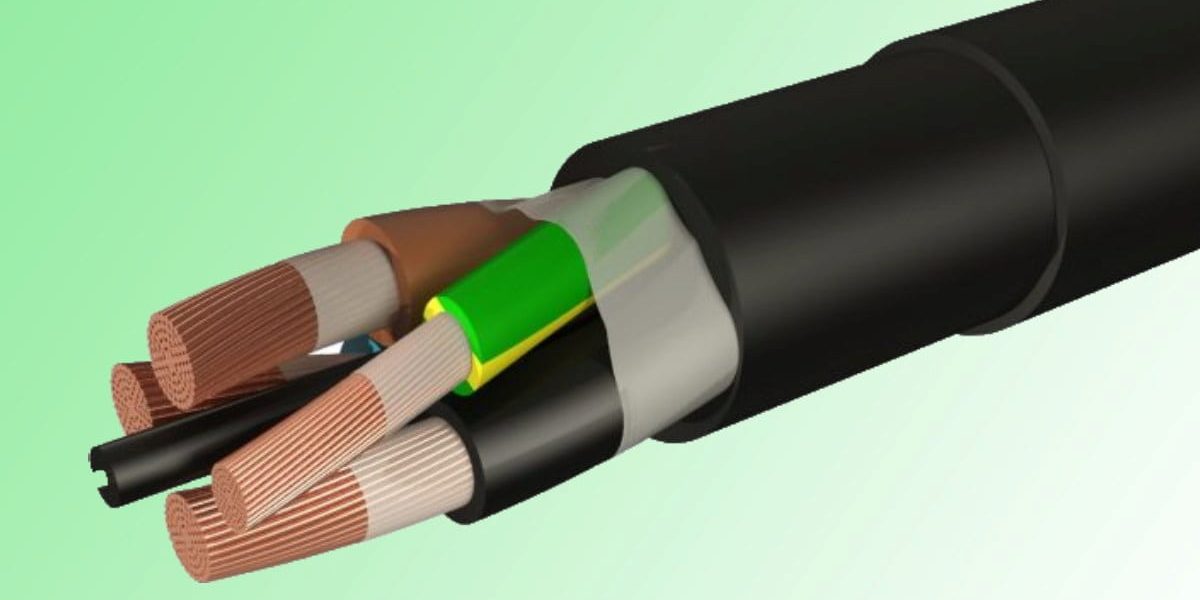

XLPE Armor A conductor insulated with XLPE is encased in XLPE armor

XLPE armor is meant to protect XLPE insulation from damage during installation and use

3

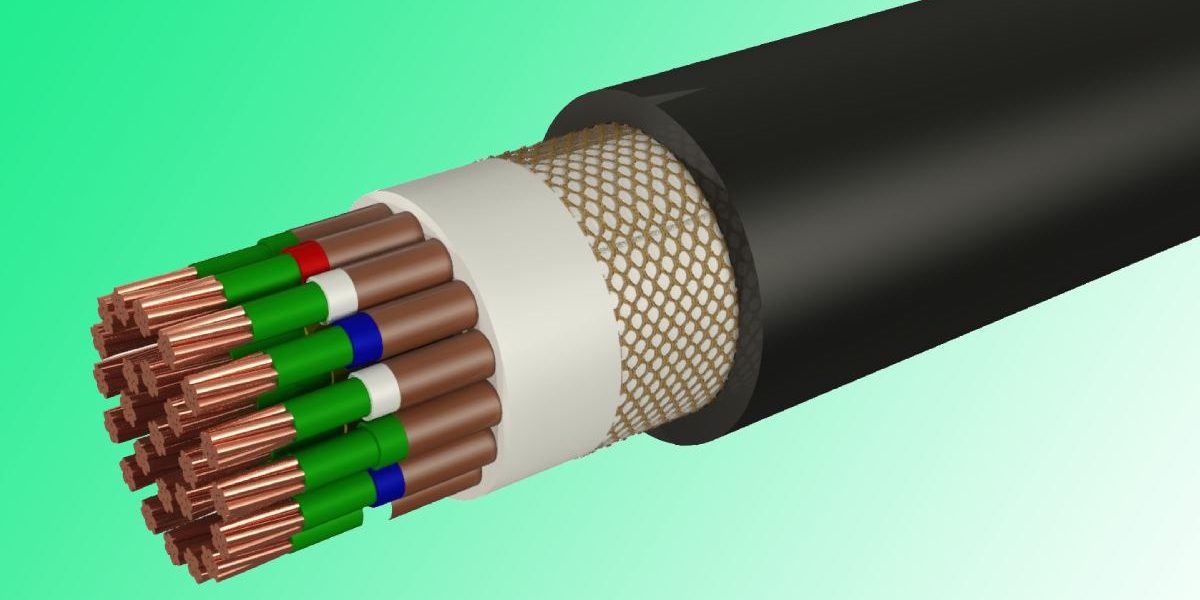

filament of cross-linked polyethylene XLPE wire is a conductor insulated with XLPE and is available in a range of diameters

The only difference between XLPE wires and standard XLPE insulated conductors is the absence of an outer jacket

Depending on the application, the price difference between armored and unarmored cables may vary

If you choose to purchase a specific length of cable, the price will be determined by the number of meters ordered

If you wish to purchase many lengths of cable, however, the price per meter will play an important impact

Cost-influencing elements of armored cables Numerous variables affect the price of armored cable, including:

Purchased meters – If you require a particular length of cable, you should assess how much you are willing to pay each meter

Application Type – A certain type of armored cable may be required for a particular application

Installing an electrical switchboard, for instance, requires a different type of armored cable than protected power wire

Grades – Various grades of armored cable offer varying degrees of protection and durability

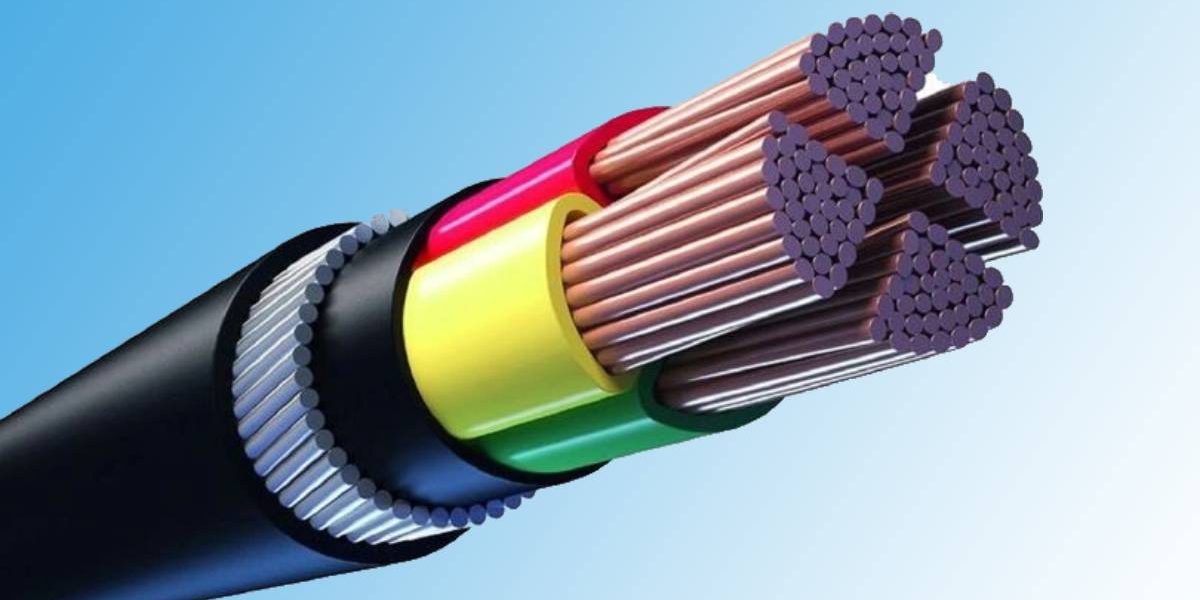

Types of available armored cables There are two types of armored cables: single wire and double wire

A single conductor is encased by a layer of steel in single wire armored cables

Two-wire armored cable consists of two conductors encircling a central insulator

Variations of each type of armor

Advantages of utilizing armored cables The use of armored cable provides numerous advantages over the use of ordinary, unarmored cable

These consist of:

Corrosion Protection – Metal shields protect wires exposed to water from corrosion and damage

Anti-Electrostatic Discharge (ESD) — Metal shields defend against electrostatic discharge, which happens when static electricity accumulates on persons or things

Immunity to Electromagnetic Interference (EMI) – The shield prevents external interference from influencing the cable’s signal transmission

xlpe armoured cable

It is not a surprise that armoured XLPE is currently the most popular type of high voltage power cable

It was created in the 1980s in an effort to lessen the incidence of electric shock incidents

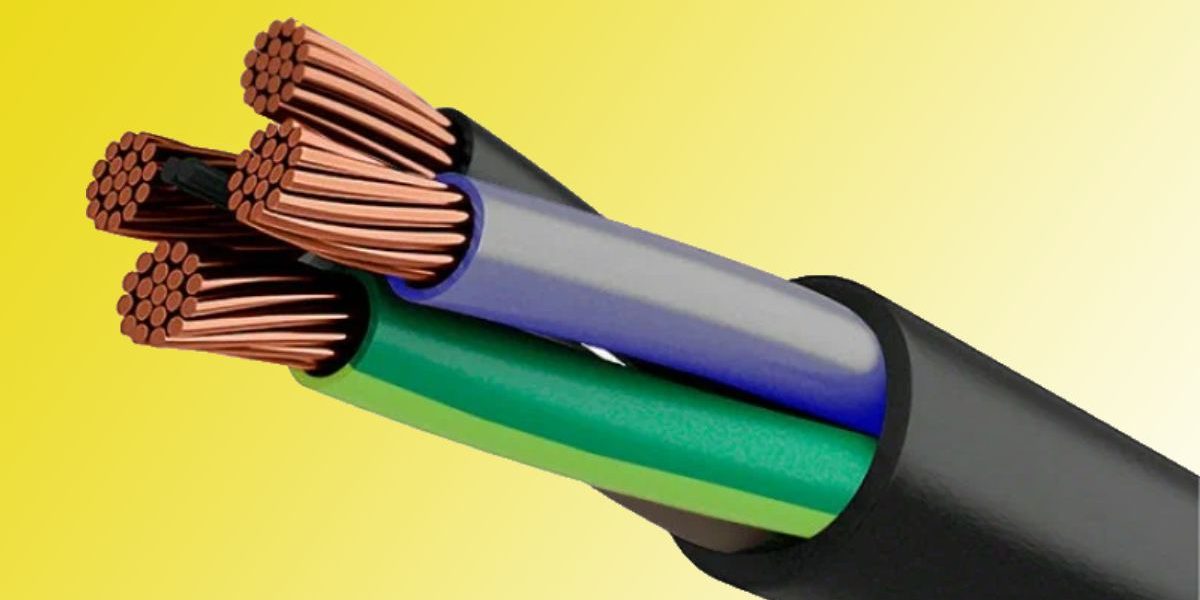

XLPE cables are constructed with two layers of polyethylene, one layered within the other

Cross-linking these inner layers makes them stronger than standard PE wires

XLPE is frequently utilized in power transmission networks, substations, and industrial applications, among other places

The cross-linking procedure requires the use of peroxide-based chemicals

These compounds link polyethylene molecules to make an exceptionally durable substance

The final product is a cable that is stronger than the original PE cable

Cross-linking makes XLPE cables resistant to oil and water and capable of withstanding high temperatures without melting

XLPE cables provide various advantages over ordinary PE cables

First, they are more robust and durable

Additionally, they have a lengthy lifespan

XLPE cables are less susceptible to corrosion than conventional PE cables and do not melt when heated

Lastly, the production of these cables is less expensive than that of PE cables

A significant drawback of XLPE cables is that they are difficult to manipulate

It takes time to cut and split XLPE cable, but once you get the feel of it, it becomes simple

XLPE cables are also not suited for use in all conditions, which is another downside

If you reside in a very cold climate, XLPE cables may not be suitable

A material used for sheathing cables is called cross-linked polyethylene (XLPE)

The cross-linking that occurs between the molecules of plastic is where the term “plastic” originates from

These linkages are created during the manufacturing process by applying high pressure and maintaining a high temperature

The wires included within an electrical cord are shielded with XLPE to protect them from any sharp things that may come into contact with them

If the broken wires are not fixed in the right way, there is a risk of sparks and fires

The purpose of XLPE armor is to prevent wires within a cable from being damaged in the event that the cable itself is cut

When it comes into touch with moisture, the cable undergoes an expansion process

Because of this expansion, the wire’s insulation may break and become exposed as a result

The wires are vulnerable to damage once they have been exposed

To stop this from happening, XLPE armor creates a barrier between the star and the environment it resides in

XLPE is a popular cross-linked polyethylene utilized in underground utility applications

It is a sort of plastic that has been cross-linked to make a durable material

It is thicker and resistant to corrosion than typical copper cables

The purpose of armored cable is to prevent physical harm

Wrapped around the steel armor for added protection are these wires

The cable is protected by three layers

The first layer consists of PVC insulation, the second of aluminum tape, and the third of XLPE

Crosslinking is a chemical interaction between the molecules of two different substances

In this instance, we are discussing XLPE versus PVC

When these two chemicals mix, a stronger substance is produced

A coating is a material put to the surface of an object to improve its appearance

In this instance, the XLPE is coated with an aluminum strip

A metal armor is placed around the exterior of armored wires to protect them

This stops anyone from slicing them and causing internal damage