Klj xlpe compound price

klj company is one of the most important manufactures of polyethylene and poly vinylene chloride they regard the following criteria as determining in the price of xlep compound

Numerous parameters, including pipe type, size, length, wall thickness, and grade, impact the price of XLPE pipe

Pipes are graded according to their tensile strength, ductility, rigidity, and ductility

The majority of pipe producers have their own grade criteria

These grades are then ranked from 1 to 10, with 10 being the best quality

The greater the number, the more rigid the pipe

Standard pipe diameters range from 2″ to 4″

Density

XLPE (cross-linked polyethylene) cost is determined by its density

A greater density reduces the amount of material utilized per unit of space

Therefore, the cost per square foot is less than that of XLPE with a lesser density

heaviness

Cost is also affected by thickness

Pulling out thicker materials requires more time and effort

Superiority

The degree of cross-linking and the thickness uniformity of the final product influence the quality of XLPE

Higher quality goods contain fewer flaws and are hence less expensive

Volume

Cost is affected by quantity, as a bigger amount requires more raw materials per unit

Cost of raw materials

The price of raw materials fluctuates based on where they are sourced and market conditions at the time of purchase

On a more general scale the price of XLP material depends on a variety of criteria, including the material’s quality, the volume of material utilized, and the size of the order

Numerous varieties of XLP materials are manufactured by various companies across the globe

Each manufacturer manufactures its own distinct form of XLP material

The quality of a product is determined by its purity, the additional chemicals, and the presence of contaminants

If the material includes impurities, it may not function satisfactorily in certain applications

High-quality materials are typically more expensive than low-quality ones

The price of XLP material is also determined by the amount of material employed

Small amounts of high-quality material are typically more expensive than huge amounts of low-quality material

Ultimately, the price of XLP material is determined by the quantity ordered

The greater the order amount, the lower the order quantity that surpasses the available material

If you purchase a large quantity of XLP material at once, the unit cost will be greater

Always attempt to purchase limited quantities of XLP material at a time to maintain pricing stability

Length, gauge, wall thickness, and plastic type are among the variables that influence the price of XLPE pipe

Keep in mind, while purchasing XLPE pipe, that the thicker the wall, the greater the price per foot

Also, a thinner tube will be less expensive than a thicker tube

Consider purchasing premade plumbing if you wish to save cash

Prefabricated, pre-sized, and ready for usage

You need not be concerned with trimming them to match your project

Klj xlpe compound

In India there are dozens of factories which manufacture polyethylene or pvc material and their offshoots like xlpe compound

Klj is a prominent factory particularly active in producing Hight quality hdpe and xlpe compound

XLPE (pronounced XLPE) is a proprietary technology created by X-Labs that delivers high-concentration dosages of electrolytes, trace minerals, and vitamins directly to the roots of plants

Unlike conventional fertilizers, XLPE is activated without water and produces consistent effects over time

Applying a tiny quantity of XLPE to the root zone of each plant is the initial step in applying XLPE

The application rate for XLPE is 1/16 ounce per square foot

Following the application of XLPE, the prescribed amount of fertilizer should be applied to the plants

No Water Needed – Because XLPE does not contain water, there is no need to water the plants while they are actively absorbing nutrients

Even if you do not water your plants throughout the season, they will continue to receive nutrients

Consistent Results – Year after year, regardless of environmental conditions, XLPE produces consistent results

EASY TO APPLY – Use a garden hose, sprayer, or spray system to apply XLPE

It is not necessary to pre-mix XLPE with water before to usage

Safety for Pets – Pet owners appreciate that XLPE is safe for their animals

Child-Safe – Children adore the idea that XL PE is child-safe

Friendly to the environment – XLPE is non-toxic, biodegradable, and recyclable

Economical – XLPE is significantly less expensive than conventional fertilizers

Adaptable to Any Environment – XLPE performs well in both indoor and outdoor settings

Using cross-linked polyethylene

Adhere to the instructions on the product’s label

Apply XLPE directly to the plant’s root zone

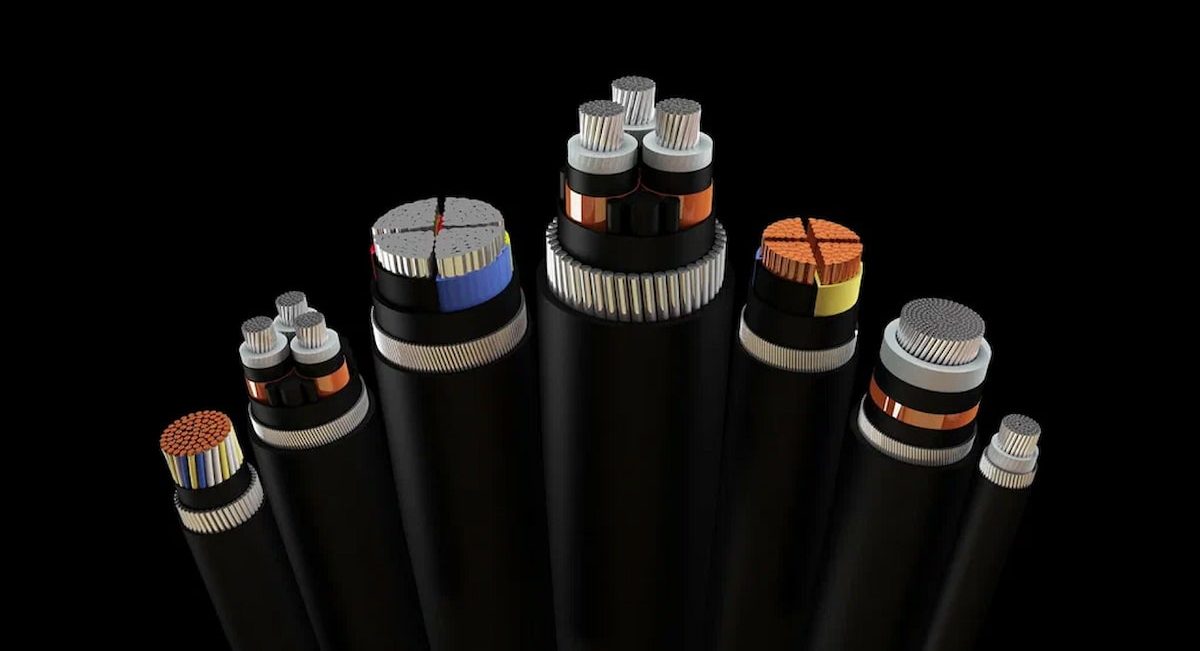

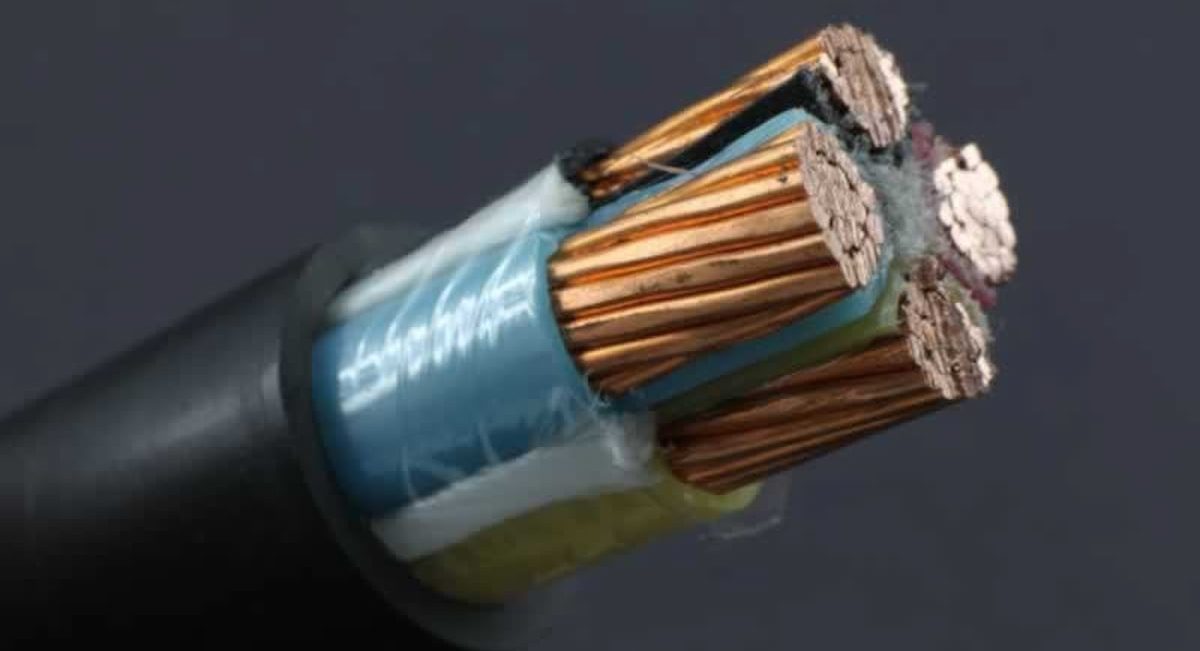

Cross-linking is the chemical method used to create XLPE (cross-linked polyethylene)

The procedure entails combining two distinct compounds, heating them at high temperatures, and then allowing them to cool to room temperature

When these substances react, they produce long-chain molecules linked together by covalent bonds

These combinations render XLPE durable and sturdy

Cross-linking involves three steps: Step 1: Combine the monomers

Monomers are the building components from which bigger molecules are assembled

To produce XLPE, ethylene monomer and vinyl acetate monomer must be combined

second step: heat the monolith After the monomers are combined, they are subjected to high temperatures to promote their reaction

The faster the monomer reacts, the greater the temperature

Once the monomers have been sufficiently heated, they begin to polymerize and create ever-lengthier chains

At some point, the monomers will become too thick to flow freely, and the mixture will become rigid

The monomer cannot continue to react at this stage

Step 3: Let the mixture cool After reaching a high temperature, the monomer was cooled to normal temperature

Due to the fact that the monomers were formerly at greater temperatures, they prefer to maintain a consistent temperature

Consequently, the monomers will begin to spin once more, causing the mixture to cool

As monomers move apart from one another, they will eventually join with other monomers to form chains that are longer and stronger