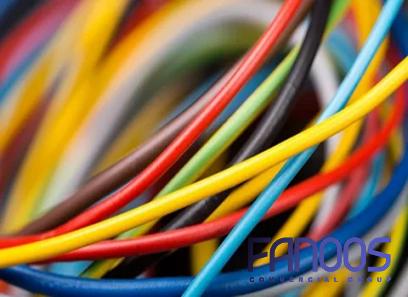

In the realm of industrial applications and electrical devices, magnet wire plays a crucial role as an indispensable component. Known for its high electrical conductivity and efficient energy transmission capabilities, magnet wire is a key facilitator in various industries, such as automotive, energy, electronics, and telecommunications. In this article, we will explore the fundamental characteristics, manufacturing process, and the diverse applications of magnet wire in today’s world. 1. The Basics of Magnet Wire: Magnet wire, also known as winding wire or enameled wire, is an insulated copper or aluminum wire that is specifically designed to carry electrical energy. The insulation is typically made from materials like polyurethane, polyester, polyimide, or polyesterimide, which provide protection against environmental factors such as temperature, abrasion, and chemical exposure. The choice and quality of insulation play a vital role in ensuring the durability and performance of magnet wire. 2. Manufacturing Process: The manufacturing process of magnet wire involves multiple steps to achieve the desired electrical and mechanical properties. It begins with the selection of the conductor material, copper or aluminum, where copper is the preferred choice due to its superior electrical conductivity. The selected conductor is then drawn through a series of dies to reduce its diameter while increasing its length. This process is known as wire drawing.

.

Following wire drawing, the conductor is coated with a layer of insulation through an enameling process. Different methods, such as solvent-based coating or high-speed extrusion, can be used to apply the insulation material. After insulation, the wire is typically baked at high temperatures to remove any solvents and cure the enamel, ensuring a durable insulation layer. 3. Applications of Magnet Wire: Magnet wire finds widespread use in a diverse range of applications. Here are some prominent examples: – Electric Motors: Magnet wire is extensively used in electric motors for various industries, including automotive, appliances, and machinery. Its high electrical conductivity and thin profile enable efficient energy transmission while maximizing space utilization in motor windings. – Transformers: The efficiency of a transformer heavily relies on the quality of magnet wire used for its windings. Magnet wire’s ability to withstand high temperatures and provide consistent electrical performance makes it ideal for transformers used in power distribution, renewable energy, and industrial machinery applications.

Following wire drawing, the conductor is coated with a layer of insulation through an enameling process. Different methods, such as solvent-based coating or high-speed extrusion, can be used to apply the insulation material. After insulation, the wire is typically baked at high temperatures to remove any solvents and cure the enamel, ensuring a durable insulation layer. 3. Applications of Magnet Wire: Magnet wire finds widespread use in a diverse range of applications. Here are some prominent examples: – Electric Motors: Magnet wire is extensively used in electric motors for various industries, including automotive, appliances, and machinery. Its high electrical conductivity and thin profile enable efficient energy transmission while maximizing space utilization in motor windings. – Transformers: The efficiency of a transformer heavily relies on the quality of magnet wire used for its windings. Magnet wire’s ability to withstand high temperatures and provide consistent electrical performance makes it ideal for transformers used in power distribution, renewable energy, and industrial machinery applications.

..

– Electronics: From small consumer electronics to complex electronic systems, such as computers and telecommunication devices, magnet wire plays a critical role in connecting and distributing electrical signals. Its compact size and excellent electrical properties help achieve efficient performance and miniaturization. – Coils and Inductors: Magnet wire is commonly used in the production of coils and inductors for various industries, including aerospace, medical devices, and telecommunications. These components help control electrical currents, generate magnetic fields, and store energy. 4. Advancements and Future Prospects: As technology continues to evolve, magnet wire manufacturers are constantly exploring innovative insulation materials, such as nanocomposites and epoxy-based solutions, to enhance electrical performance further and improve durability.

– Electronics: From small consumer electronics to complex electronic systems, such as computers and telecommunication devices, magnet wire plays a critical role in connecting and distributing electrical signals. Its compact size and excellent electrical properties help achieve efficient performance and miniaturization. – Coils and Inductors: Magnet wire is commonly used in the production of coils and inductors for various industries, including aerospace, medical devices, and telecommunications. These components help control electrical currents, generate magnetic fields, and store energy. 4. Advancements and Future Prospects: As technology continues to evolve, magnet wire manufacturers are constantly exploring innovative insulation materials, such as nanocomposites and epoxy-based solutions, to enhance electrical performance further and improve durability.

…

Additionally, efforts are being made to develop magnet wires with reduced environmental impact, focusing on sustainable and recyclable materials. These advancements will enable magnet wire to meet stringent requirements of cutting-edge applications such as electric vehicles, renewable energy systems, and next-generation communication networks. Conclusion: Magnet wire’s exceptional electrical characteristics combined with its versatility make it an indispensable component in various industries. Its ability to efficiently transmit electricity while resisting environmental factors and wear ensures the reliable operation of critical systems. As technology continues to advance, the evolution of magnet wire will pave the way for more efficient and sustainable electrical solutions, bringing about enhanced performance and durability in numerous applications, ranging from consumer electronics to complex industrial systems.

Additionally, efforts are being made to develop magnet wires with reduced environmental impact, focusing on sustainable and recyclable materials. These advancements will enable magnet wire to meet stringent requirements of cutting-edge applications such as electric vehicles, renewable energy systems, and next-generation communication networks. Conclusion: Magnet wire’s exceptional electrical characteristics combined with its versatility make it an indispensable component in various industries. Its ability to efficiently transmit electricity while resisting environmental factors and wear ensures the reliable operation of critical systems. As technology continues to advance, the evolution of magnet wire will pave the way for more efficient and sustainable electrical solutions, bringing about enhanced performance and durability in numerous applications, ranging from consumer electronics to complex industrial systems.

Your comment submitted.